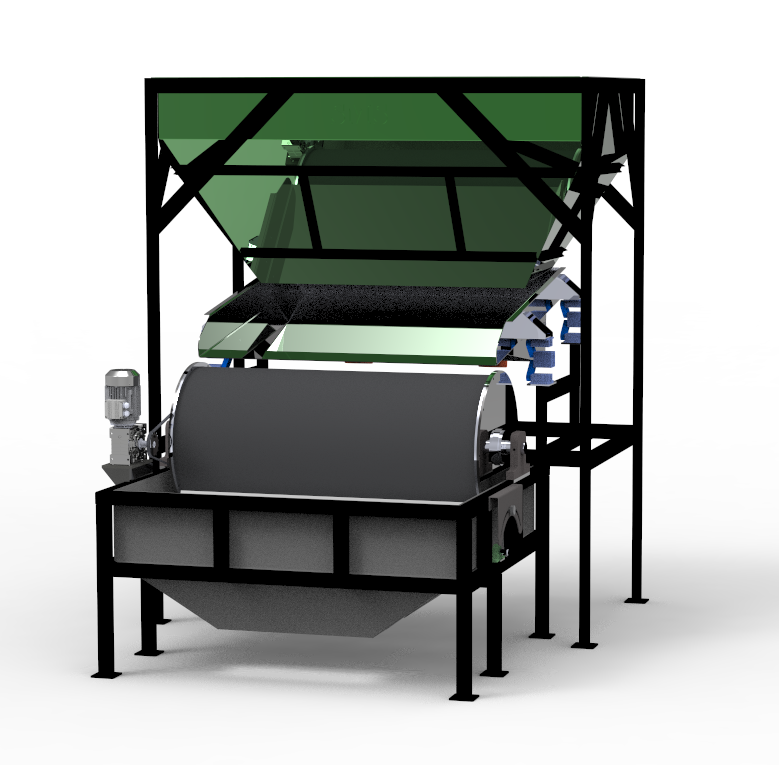

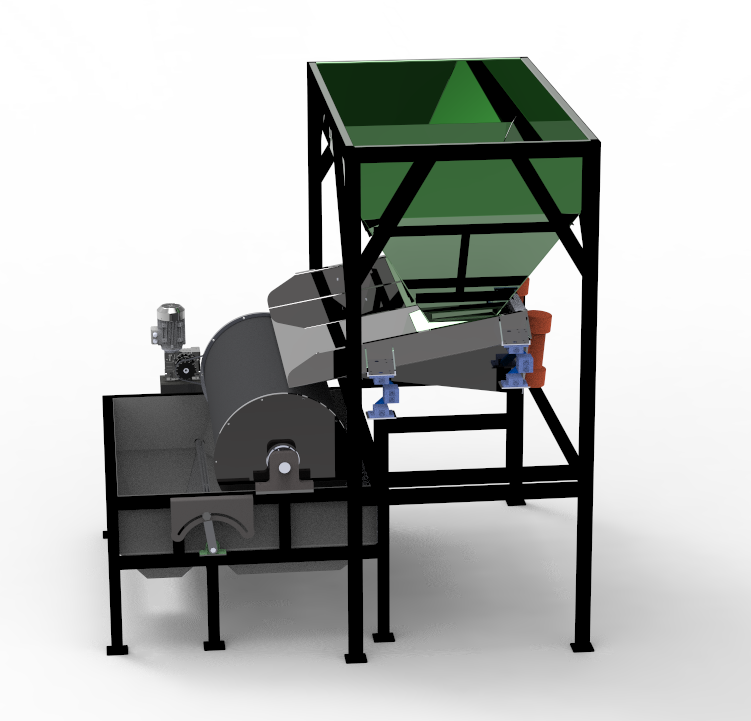

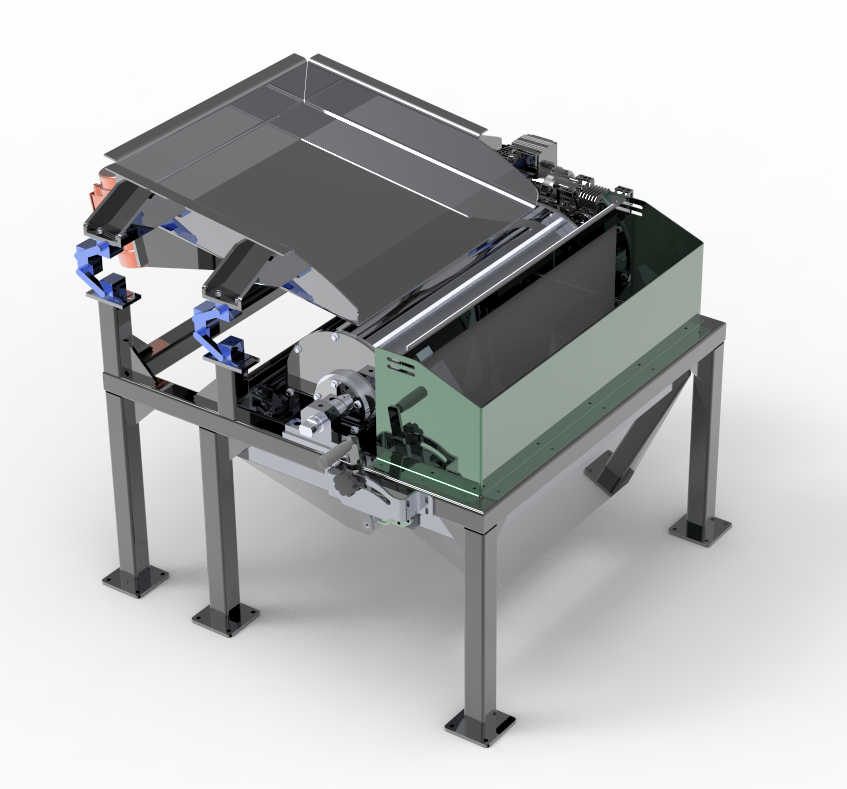

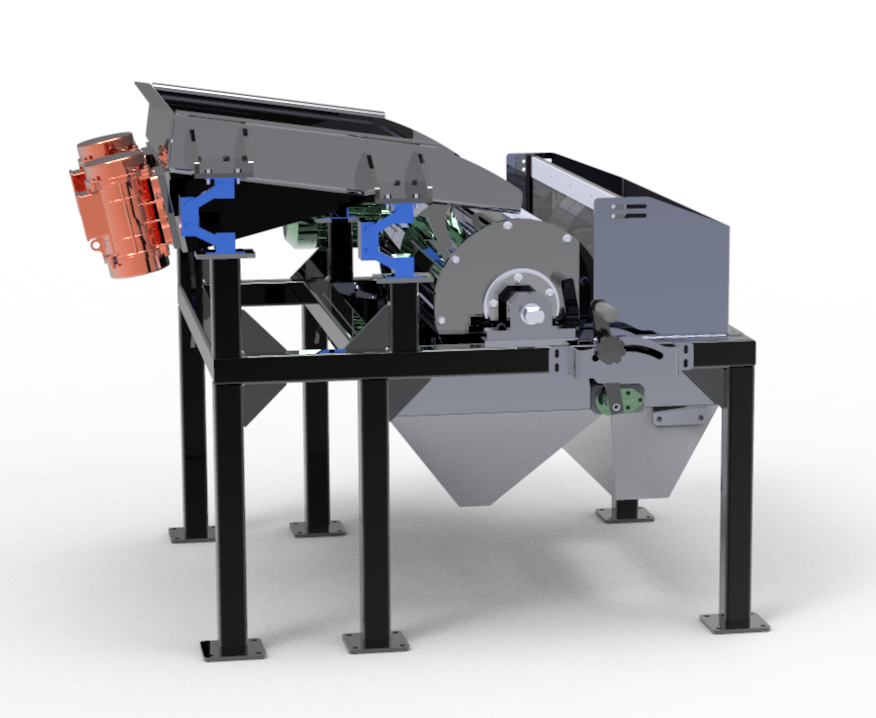

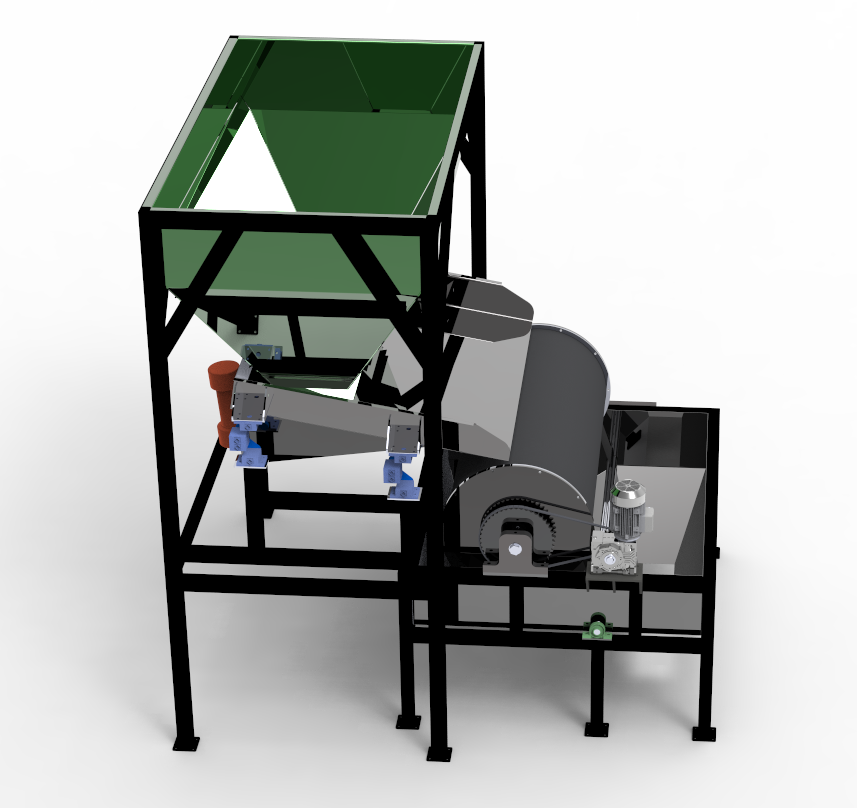

Dry magnetic drum separators are one of the primary pieces of equipment playing a crucial role in the iron ore beneficiation process. These separators are used to separate other gangue minerals from iron ore and are widely preferred in the industry. The process begins with the iron ore being fed from the top feed hopper to the magnetic drum via a vibro feeder. The separation operation concludes by separating ore and waste through the separation flap at the bottom hopper. The magnetic field attracts iron-containing particles, which accumulate on the drum surface. Other minerals are unaffected by the magnetic field and follow a different path. This ensures high efficiency in the iron ore beneficiation process, yielding high-quality iron concentrate. The magnetic force on the drum surface is provided using special alignment methods in the core, with Neodymium and ceramic magnets suited to the ore's mineralogical structure. Dry magnetic drum separators are effective and reliable equipment widely used in the mining industry, raw material purification processes, food industry, and recycling sectors. They are applicable for particle sizes ranging from +1 mm to -400 mm and dry granules. We manufacture drums with diameters ranging from 300 mm to 1200 mm and lengths up to 3000 mm, tailored to capacity requirements.