Transformer Industry Application

Vacuum oil filling furnaces used in the transformer industry are specialized pieces of equipment designed to carry out the oil filling process under vacuum. By filling transformer oil under high vacuum, these furnaces prevent oxygen and moisture from entering the oil, maintaining its quality and ensuring better absorption of the oil into the gaps between insulation materials, thus eliminating air pockets.

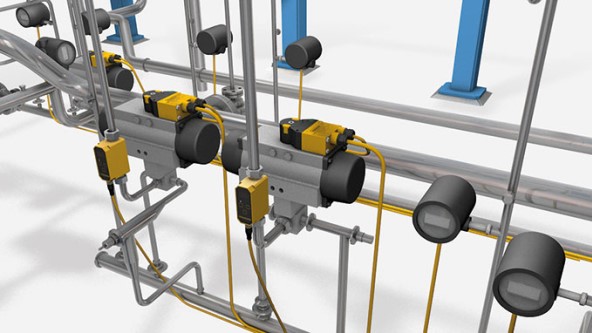

The oil filling process is controlled using sensors, precise flow meters, and pneumatic valves, and is designed with a flexible interface to meet user requirements. All equipment used is made of stainless steel for durability.

Features of Vacuum Oil Filling Furnaces:

Vacuum Pumps

High-performance vacuum pumps are used to create the necessary vacuum. These pumps ensure that the vacuum level is maintained as required during the oil filling process. The system consists of vane and root pump sets.

Oil Storage Tank

Refined and prepared transformer oil is placed in special storage tanks. These tanks are insulated to maintain the desired temperature and prevent excessive energy consumption.

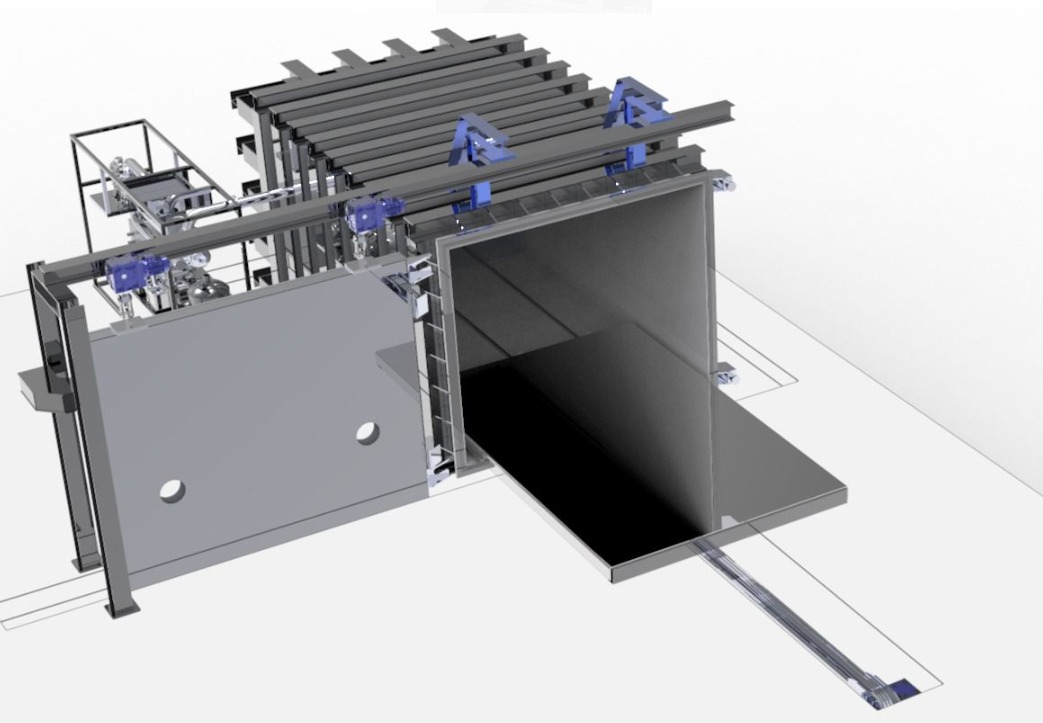

Vacuum Chamber

A vacuum chamber or cabin is used for the oil filling process. These chambers are designed to withstand vacuum conditions. They isolate the oil from external influences during filling and ensure that the process is carried out under vacuum conditions.

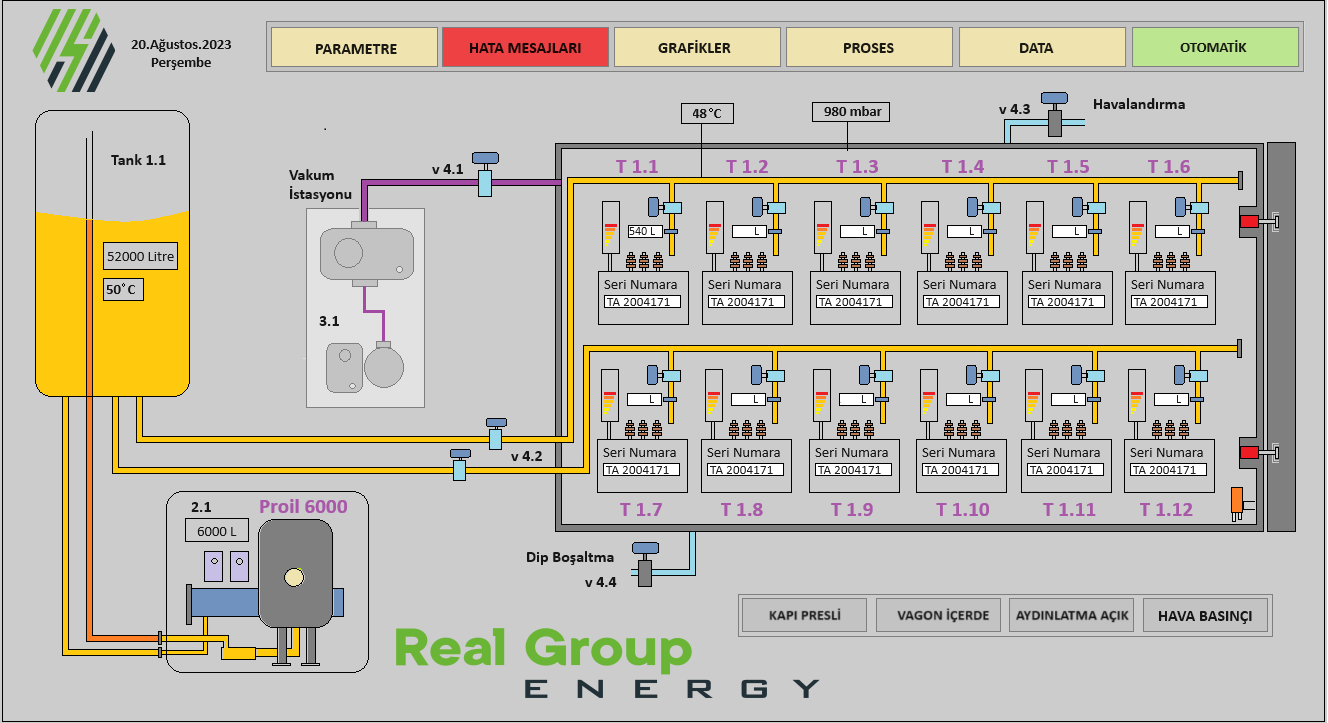

Control Systems

The oil filling process is managed by precise control systems. These systems continuously monitor and control vacuum levels, oil temperature, oil levels, and other critical parameters to ensure optimal operation.