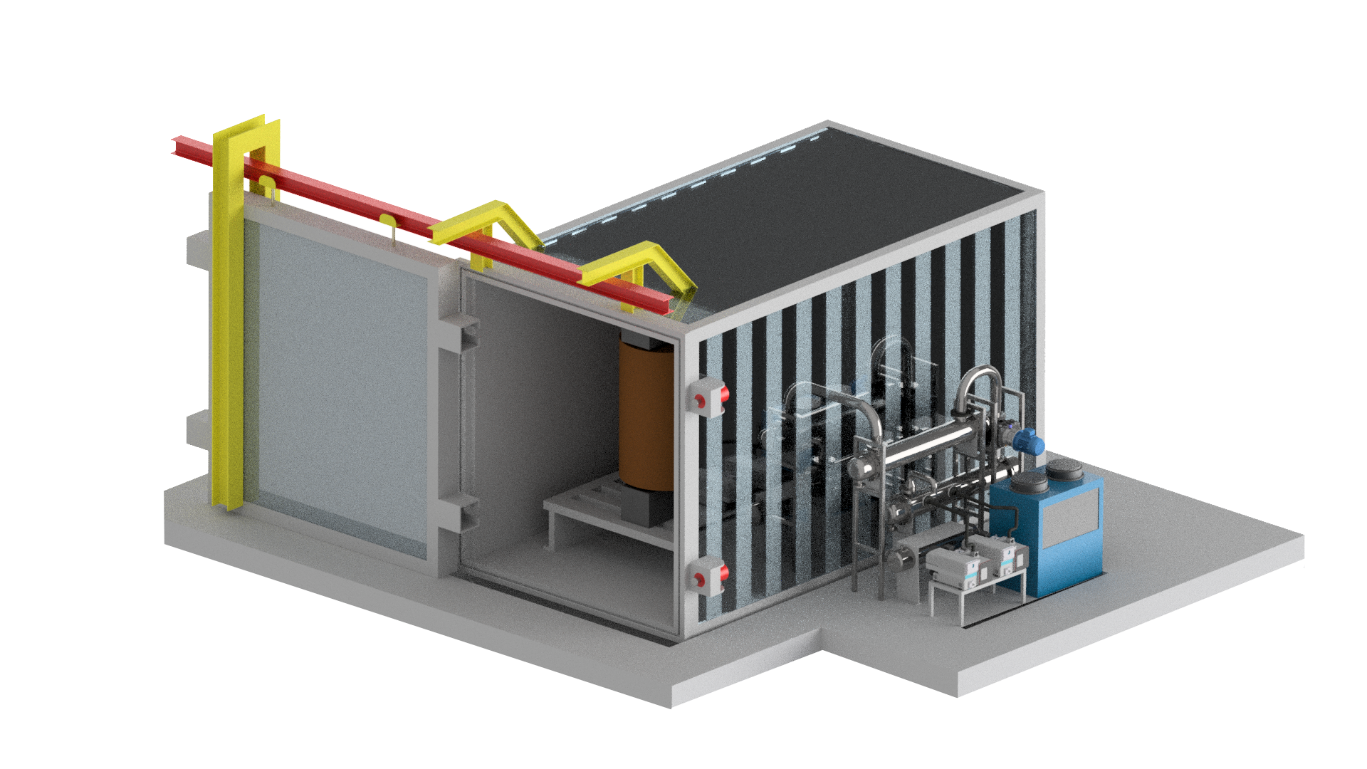

In the transformer industry, one of the most crucial stages for producing high-quality and reliable products is the purification and drying of insulation materials. Vacuum ovens play a vital role in this stage, determining the capacity of the transformer plant. Vacuum ovens ensure the desired properties of transformer coils and insulation materials, enhancing the durability and performance of the final products.

Their modular structure makes transportation and installation easy. Their compact design provides everything in one unit, saving space. The processes are fully automatically controlled.

Features and Benefits of Vacuum Ovens:

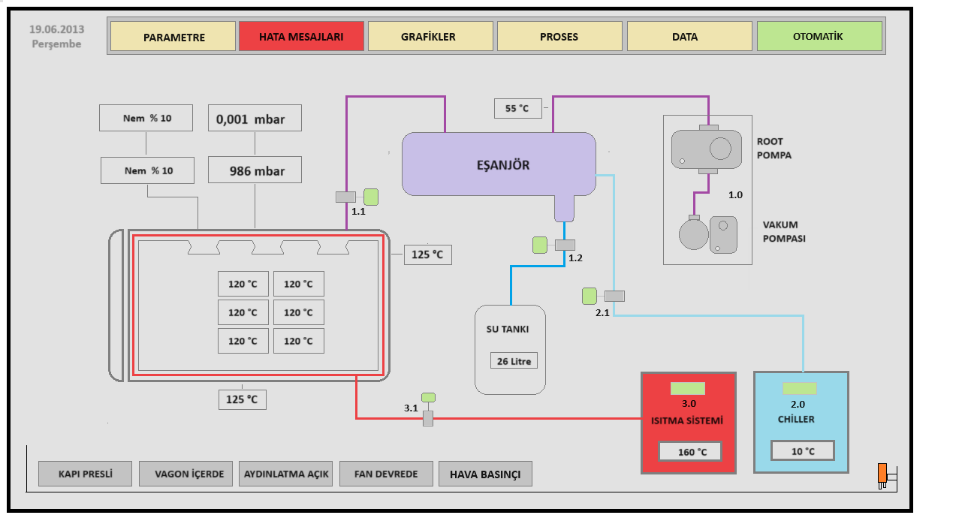

Vacuum Resistance Under Homogeneous Temperature: Vacuum ovens perform reliably even in high vacuum and pressure environments, ensuring the long life and reliability of transformer components.

Homogeneous Heat Distribution: Ensures uniform drying of insulation materials, with air circulation provided by vacuum-resistant special fans.

Fast and Efficient Process: Vacuum ovens minimize process times with high heating and cooling rates, thus increasing production efficiency. Processes are optimized through real-time control with sensors.

Environmentally Friendly: Vacuum ovens consume minimal energy for drying insulation materials, and all equipment used in the system is efficient and long-lasting, promoting an environmentally conscious production process.

Flexible Use: With the ability to process transformer components of different sizes and shapes, vacuum ovens have a wide range of applications in the industry.

Vacuum drying ovens play a critical role in producing high-quality and reliable products in the transformer industry. Due to their high performance, efficiency, and environmentally friendly features, the ovens we manufacture at Real Group are leaders in their field.