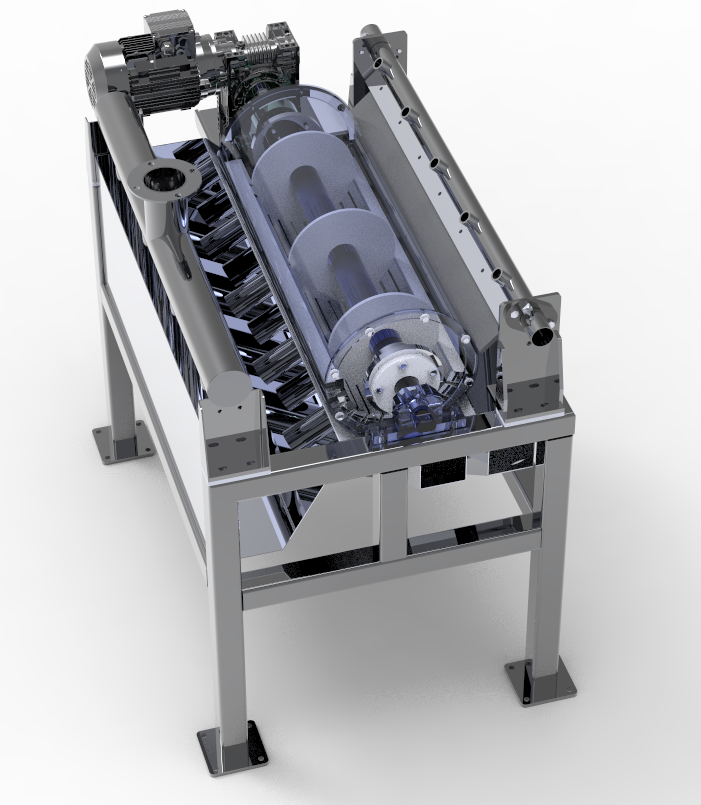

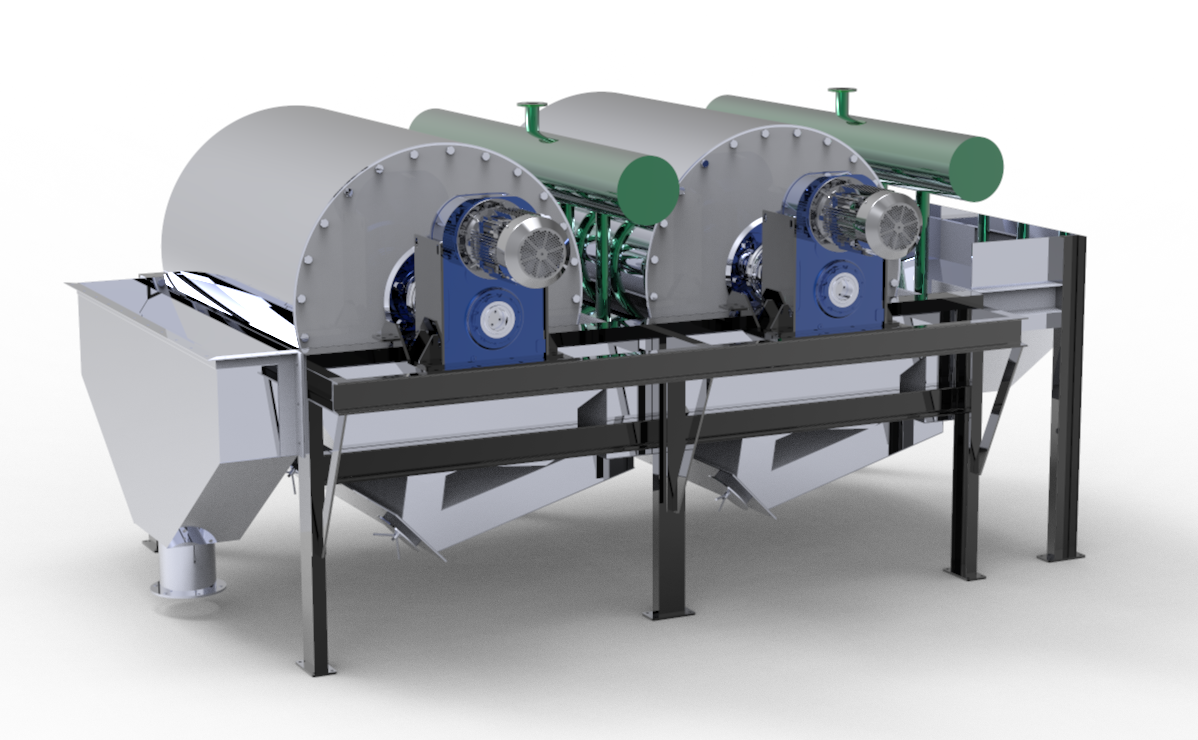

Wet Magnetic Drum Separators are used in micronized iron ore beneficiation processes. In applications dominated by liquid flow processes, wet magnetic drum separators are preferred for ore enrichment purposes. The material is fed onto the drum separator via a feeder, where magnetically susceptible material is attracted to the drum surface due to the magnetic field. As the drum rotates, magnetic minerals are separated from the system through magnetic polarization. Non-magnetic materials are not captured by the drum and are expelled from the waste section of the separator via the discharge collector. At the end of the system, magnetic material is separated from the desired product flow, enhancing product purity and plant productivity. This prevents potential leaks during ore enrichment and maintains the quality of the concentrate. These separators are effectively used, especially in coal mines, for the recovery of magnetite, which is used as a dense medium.